Integrated Water Solutions

Eco-Friendly Sustainable Solutions for Water Conditioning

Why Choose Integrated Water Solutions?

Integrated Water Solutions is dedicated to providing our customers with the best solution for their needs. Each application is engineered to achieve optimum efficiency, while saving money on operating, maintaining, and automating their system. IWS uses HydroFLOW technology to combat new and existing scale, biofouling, and corrosion through its powerful and safe 150kHz signal. Because of the HydroFLOW’s ability to enhance filtration, we provide engineered filtration solutions at customers request to further optimize cost savings and system automation.Integrated Water Solutions can develop an environmentally friendly solution tailored to your needs, resulting in a cleaner and more efficient system. Contact US Today

Learn About HydroFLOW?

What How it Works

What is HydroFLOW?

HydroFLOW¬is a noninvasive water conditioner that uses¬Hydropath Technology¬to reduce operating costs, increase energy efficiency, improve water quality, reduce fouling, decrease chemical usage, and prevent costly production stoppages. Effective for treatment of scale, algae, bacteria, corrosion, etc.

Where is HydroFLOW Used?

Typical applications include plumbing networks, water heaters, boilers, heat exchangers, belt filter presses, cooling towers, wells and pumps. In demand sectors include industrial, commercial and agricultural.

HydroFLOW

Water Conditioning Technology

Authorized Distributor

Please Let us Know if You Have Any Questions

Why HydroFLOW/HydroPATH Technology

Unlike other products that treat liquids at a single point in a system and whose impact starts to diminish instantly after that point,¬HydroFLOW¬†provides continuous water conditioning ensuring a dependable and ongoing effect.

Due to its exclusive, non-intrusive design,¬HydroFLOW¬†doesn‚Äôt add any chemicals to your water supply while hindering pipe corrosion and exterminating algae and bacteria.

Additionally, while it protects your equipment, it’s easy to install, energy efficient, and requires no maintenance or wasted space.¬

IWS provides turnkey solutions based on understanding the customer's needs:

Consulting

Design

Engineering

Metering

Monitoring

Fully Customizable Installation

Sales / Leasing

Guaranteed Service

Scale - Costly & Decreases Efficiency

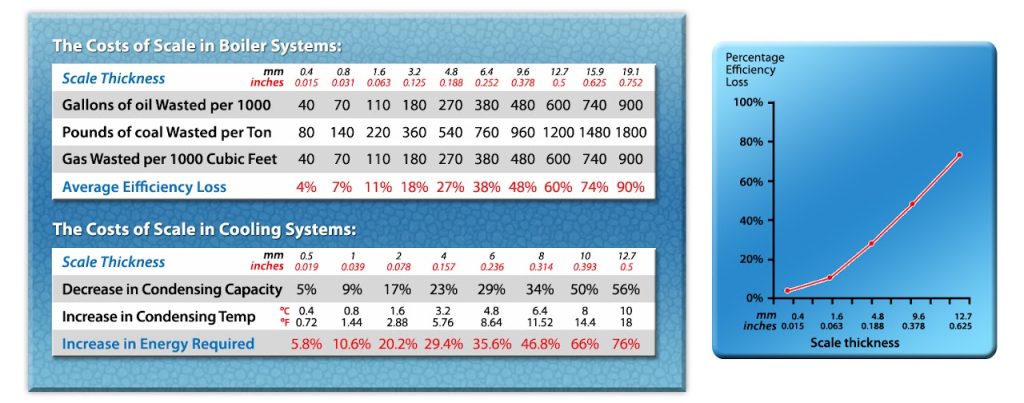

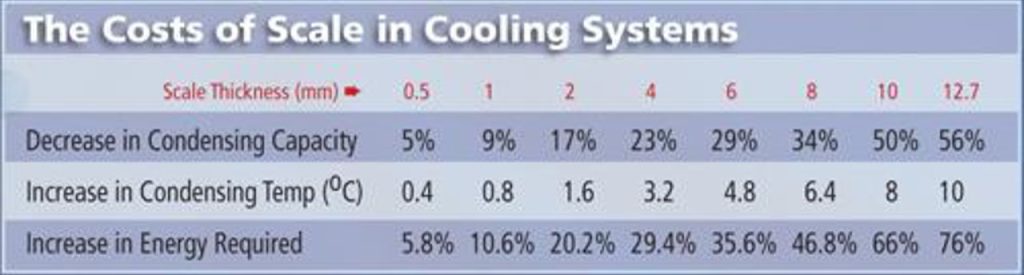

Scale deposits typically occur when the concentrations of dissolved minerals in the cooling water exceed their solubility limits and accumulate on heat exchanger surfaces. The most common scale former, calcium carbonate, exhibits reverse solubility in that they become less soluble as the temperature of the water increases. This property causes scale formation and build-up on heat transfer surfaces of equipment.

Because the thermal conductivity of scale is substantially lower than metal, scale deposits typically reduce the heat removal capability of the equipment, and production speeds must be lowered to compensate. In extreme cases, enough scale accumulation can block cooling water passages and affect equipment efficiency. Scale formation on the condenser of chillers reduces the efficiency of these units in chilled water systems, therefore requiring an increase in the amount of power needed to obtain a given volume of chilled water.

The HydroFLOW/HydroPATH technology charges the ions in the water, positively and negatively causing the particles to become attracted and form clusters that stay suspended in the solution instead of building up on equipment surfaces. In addition, the HydroFLOW signal affects existing scale in heat exchanger systems causing it to be attracted to the charged particles suspended in the solution aiding in the removal of existing scale throughout the system. The prevention and removal of scale on heat transfer surfaces allows the system to run at a higher mineral concentration, thus reducing or eliminating the need for scale inhibiting chemicals. Less chemicals = more eco-friendly.

Fully Customizable

HydroFLOW can be customized to meet larger customer specifications and is also available in standard configurations.

Larger pipes use more powerful¬HydroFLOW¬†units.

Ferrite rods and nylon hardware easily replaceable if damaged.

Fully encased and submersible.

Operates in a wide variety of elemental conditions.

Enhances Filtration Efficiency

The¬HydroFLOW¬†device flock suspended particles that pass through the ring of ferrites,¬so they¬†filter out of water systems more effectively. The increased filtration¬performance¬†can reduce backwashing by a factor of¬3, and the amount of water used in each backwash cycle is reduced by up to¬fifty percent.¬Reduced backwashing means¬lower expenses for water usage and maintenance downtime.¬†In¬certain wastewater applications,HydroFLOW¬†can assist with increased cake dryness and¬polymer reduction.

Electric Water Conditioning Benefits

Reduces 20-50% of make-up water demand

Reduces disposal volumes by 50-100%

Reduces chemical use by approximately 75%

Controls biofouling and algae

Improves filtration by flocculating particulates

Conserves approximately 12% kWh per month

Reduces Maintenance and Extends Asset Life

Simple to Install and has No Moving Parts